Thermal plastic is one of those products that is widely used in the field of packaging. Using this product, you can pack any product and gender you want and then press it with heat. With this, dust is prevented from sitting on the product, and the products are placed together and packed in an orderly manner.

What is thermoplastic?

Thermal plastic, which is also known as Thermal vacuum or Nylon shearing, is actually a plastic cover that shrinks against heat. The good feature of this nylon is that the desired product has any shape and appearance, it sticks to the product and vacuums it. The way to use the thermal plastic film is that first you have to cut a certain size of it and put it around the object that is going to be insulated. Then it should be heated using a suitable heat source such as an industrial hair dryer. This plastic cover does not melt under the influence of heat and only shrinks. With this method, while the coating is completely strong and durable, it is also transparent so that the product can be easily seen.

Application of thermal plastic

In various industries, thermal plastic is used to store several products of the same shape together. The food industry, ceramic tiles, auto spare parts, household appliances, electrical parts, toys, etc. are some examples of industries that use this type of nylon to package their products. In factories and industrial centers, product packaging is done using a device called shearing pack. After closing the product with nylon and heating and then cooling the product, they pack it. Mineral water packaging is one of the examples of thermal plastic packaging. But it is interesting to know that this type of plastic can be used for home use by using heating equipment such as a hair dryer. Packaging of waste papers and bags, luggage covers, blankets, books, TV controls, etc. are among the various applications of thermal plastic with a hair dryer at home.

Types of thermal plastic film

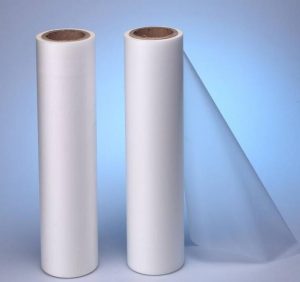

Thermal plastic rolls are produced in PVC and polyolefin (POF). PVC film is dry and has low flexibility. Polyolefin film is actually an improved version of PVC, which has a soft texture with higher flexibility, greater transparency, and better printability. Whenever transparency and durability are concerned, polyolefin film shows better results.

The price of thermal plastic

The price of this product, like other plastic products, changes according to the rate of raw materials, and for information on prices and bulk purchases, it is better to contact our sales experts. You can purchase thermal plastic online and in person through this site.

How to maintain thermal nylon rolls

- Do not stack the thermal nylon rolls on top of each other so that the cardboard tube inside them is deformed. If the cardboard tubes inside them are deformed, it will be difficult to use the roll inside the device.

- Do not place the nylon rolls vertically, because over time the nylons will slip and become conical. So keep them horizontal.

- Note that to protect the cardboard inside the rolls, never expose them to moisture.

- Thermal nylons are vulnerable to sunlight, so keep them out of the sun.

Frequently asked questions

- Is it possible to produce colored thermal plastic in your collection? Yes, this product can be presented in different colors according to the customer’s request.

- How much heat is required to work with these nylons? Heat around 150 to 220 degrees Celsius makes the nylon shrink and vacuum and stick to the product and make a strong pack for it.

- How much heat is required to work with these nylons? Heat around 150 to 220 degrees Celsius makes the nylon shrink and vacuum and stick to the product and make a strong pack for it.

- How many layers are thermal plastic films? These films are double-layered and have an intestinal state; They are open from the sides and closed from the top and bottom.

There are no reviews yet.