Cellophane is one of the most widely used polymers in the packaging and printing industry, and it comes in various types. Metallized cellophane is one of the types of cellophane that we intend to introduce and examine its features in this article.

What is metallization?

Metallized Lamination on Paper: Metallized sheet has the ability to laminate on all types of paper such as kraft, glossy and other types of paper. Some of the products that are produced from paper with metallized lamination include: butter packaging, cigarette packets, business cards, gift wrapping paper.

Metallized laminate on cardboard: Examples of metallized laminate with cardboard include hard boxes, candy boxes, and various packaging boxes.

Applications of metallized film

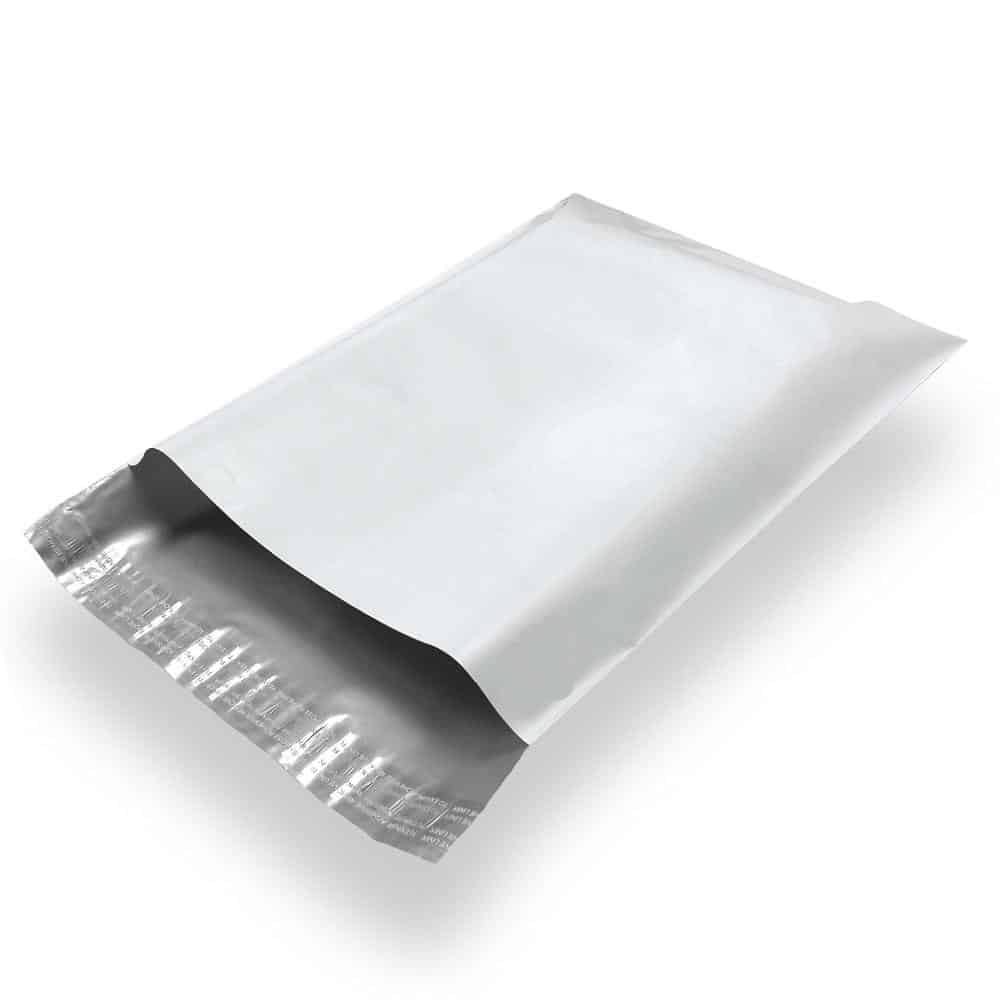

Metallized pouch: Metallized packaging pouch is essentially the same as metallized laminate with cellophane, which is produced in this way during the pouch-making stage. Due to its internal metallized layer, the metallized pouch protects its contents from sunlight, moisture, and water. This is why the food industry and dry powder and granular products, as well as liquids and wet products, are regular customers of these pouches.

Other types of metallized envelopes include paper envelopes laminated with metallization, which are used for sending letters and documents in postal organizations. These envelopes protect their contents from light, water, and humidity due to their metallized inner layer.

Metallized Labels: Another major application of metallization is in label manufacturing, which is used in many beverages, cosmetics, health products, pharmaceuticals, and food products. An important feature of metallized labels is their more attractive appearance and greater resistance than paper labels. Metallized labels can be produced in a single metallized layer or laminated with cellophane in your specific sample.

Metallized bubble wrap: If a metallized layer is added to bubble wrap, a good thermal insulator is created that is widely used in building facilities. Metallized bubble wrap is used as insulation for air conditioner ducts, splits, and windows, which prevents energy loss at a very high level.

Metallized packaging feature

As you know, the most common use of metallized cellophane is in the field of food packaging. This type of packaging film has various advantages for this purpose, which makes different manufacturers use it to package their various products. Some of the most important advantages of metallized packaging are introduced below:

What is metallized printing?

- Metallizing the entire printed surface and printing on it

- Local metallization, in which only specific parts are metallized; such as logos and specific writings.

Frequently Asked Questions

- What is the difference between metallization and aluminum foil? Metallization and aluminum foil are actually the same material, but they are different in thickness. Aluminum foil is thicker than metallization and can even be used as a single layer. Tobacco packaging is one of the uses of aluminum foil.

- Does metallized cellophane come in colors? Metallized cellophane is often known for its aluminum color, but it is also possible to produce metallized film in other colors. Gold metallized and colored metallized are no different from the silver type in terms of features and are only offered in a different color due to the presence of colored granules in it.

- What are the delivery methods for metallized cellophane? Rolled and bagged.

- Is it possible to print on metallized film? Yes. Metallized has the ability to be printed with high resolution, where even the finest details will be displayed.

There are no reviews yet.